Working principle of air compressor and its various types

This article gives a description on compressor's working and the various types available. It also gives insight on selection of compressors and ways of capacity Variations.

Compressors (Types and Principle of Working)

A compressor is a device or equipment which compresses the fluid from a low pressure to a high pressure. The fluid is distributed from a low velocity and low pressure to a high velocity and high pressure.

The main types of compressors are classified as:

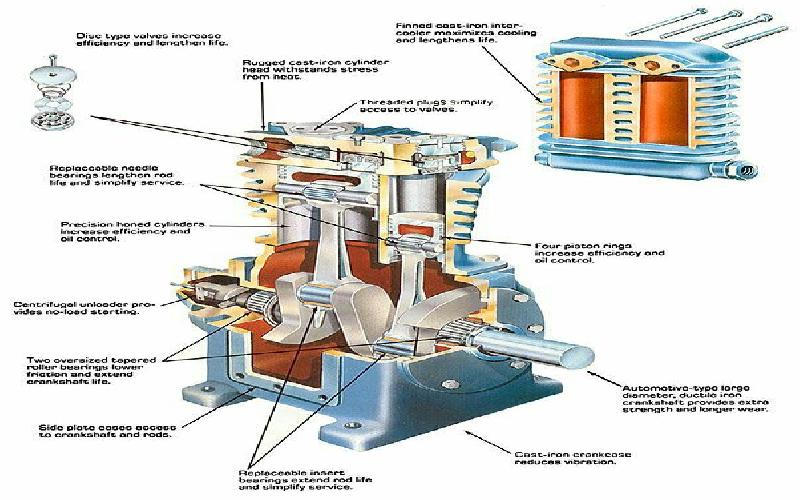

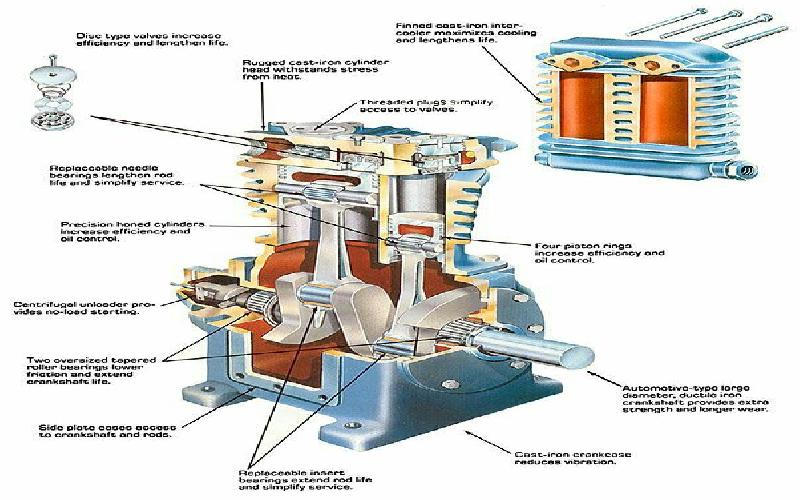

Reciprocating Compressors: As the name indicates the reciprocating compressors reciprocates to create the fluid or air at high pressures. They are positive displacement devices and usually have a Piston and the cylinder. The piston reciprocates in the cylinder and due to compression in the volume, the pressure of the gas increases and which is then delivered on a high pressure.

Reciprocating compressors are further of the types, single stage and double stage compressors. Single stage compressors are for low pressure ranges and the double or two stage compressors are for delivering high pressure ranges.

Reciprocating compressors are also of types, single acting and double acting compressors. If the piston compresses the fluid or the gas on only one side the compressor is a single acting compressor.

When the piston compresses the air on from both the sides it is considered as a double acting compressor.

Rotary Compressors: Rotary compressors utilize the rotary motion to compress the air within the cavity. They are generally of the screw types, in which the rotary motion of the screw creates the linear displacement and hence compresses the air. These rotary compressors come in wide ranges of capacity and have very wide applications. The capacity of the compressors is varied by changing the speed of rotation of the screw and also by changing the displacement. These compressors are also positive displacement equipments.

Centrifugal Compressors: Centrifugal compressors as the name indicates utilize the centrifugal action to compress the air and deliver it on high pressures. In order to achieve a high rate of compression, these centrifugal compressors are rotated at a very high speed. In order to vary the capacity of the compressor either the speed of the compressor is changed by using a variable speed drive. The change in the capacity can also be accomplished by changing the vane angles and vane openings. The centrifugal compressors are usually used for delivering high compression pressure ranges. Also they have a continuous flow.

Thus we have seen the different type of compressors. There selection and use depends on the kind of application and the capacity or the pressures required. For low capacity or low pressure conditions the reciprocating compressors are used. For high pressure and high capacity the rotary compressors and the centrifugal compressors are used. A general estimation is that for 50 to 60 hp requirements the reciprocating compressors are used and for higher hp like 100hp and above the rotary and centrifugal compressors are used.

One important aspect of these compressors is the lubrication. Most of the compressors are tried to make them lubrication free. But for some compressors the regular compression is the important need and should be done pro actively.

Intelligent people can throw a question how do you choose a particular value from a set of value. In the above example, the array is same as the set of fruits known as apple, banana, pineapple and grape.